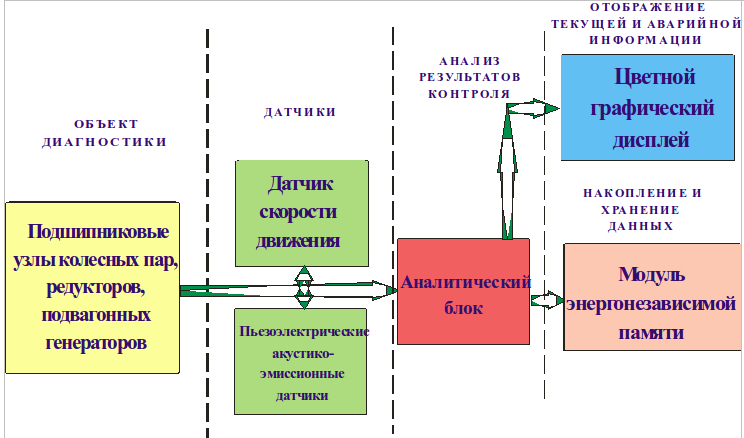

On-board acoustic emission diagnostics system of wheel-motor blocks is intended for the constant complex control of operating electric locomotive wheel-motor blocks condition; it allows to:

Developer: OOO METKATOM.

System blocks delivery, personnel training, technology of diagnosis.

System delivery and installation is performed within three months.

The cost of on-board 36-channel system (for a 6-axle electric locomotive) with account of installation and personnel training is included in the contract. System cost in case of equipping locomotive pilot batch is specified at the contract conclusion.

| PRESENT LOCOMOTIVE PREVENTIVE MAINTENANCE SYSTEM | ON-BOARD DIAGNOSTICS SYSTEM ADOPTION FOR LOCOMOTIVES |

| Periodic preventive maintenance and repair work costs with present maintenance system TO-3→TR-1→TR-2→TR-3→SR are ≈ 1,600,000 roubles per locomotive a year, out of which 35-40 % (≈ 640,000 roubles) are KMB and TED elements maintenance costs. | On-board diagnostic system of bearing units allows to reduce unreasonable expenses, thereby units maintenance estimated expenditures according to their actual condition will be ≈ 20-25 % (≈ 130,000 roubles). Hereby annual saving rate will be SR= 640-130 = 510,000 roubles per equipped locomotive. |

| Lubricant costs with the present lubricating system (at the cost of 1 kg of BUKSOL lubricant 50 roubles) are 65,000 roubles per locomotive a year. | Bearing units lubrication according to their actual need allows to reduce unreasonable operations of lubricant final squeezing and reduce lubricant consumption by 45-50 % ( ≈ 35,000 roubles per locomotive a year). Hereby annual saving rate will be SR = 65-35 = 30,000 roubles per equipped locomotive. |

| Preventive maintenance costs according to structure TO-3→TR-1→TR-2→TR-3→SR with the existing norms of overhaul life are 2,205,000 roubles per locomotive a year. | On-board diagnostics system of bearing units adoption allows to increase overhaul life by 25-30 % of the existing norms (≈1,545,000 roubles per locomotive a year). Hereby annual saving rate will be SR =2205 -1545 = 660,000 roubles per equipped locomotive. |

TOTAL ANNUAL SAVING RATE |

|

| Per equipped locomotive | SR= 510+30+660=1,200,000 roubles |

| Per locomotive depot (with the average rolling stock of 150 locomotive units) | SR=1,2 х 150=180,000,000 roubles |

OOO METKATOM technical director : V.S. Potapenko

Candidate of Science {Engineering}: D.V. Fedorov